Geared motor PR.45E

PR.45E

230 Vac

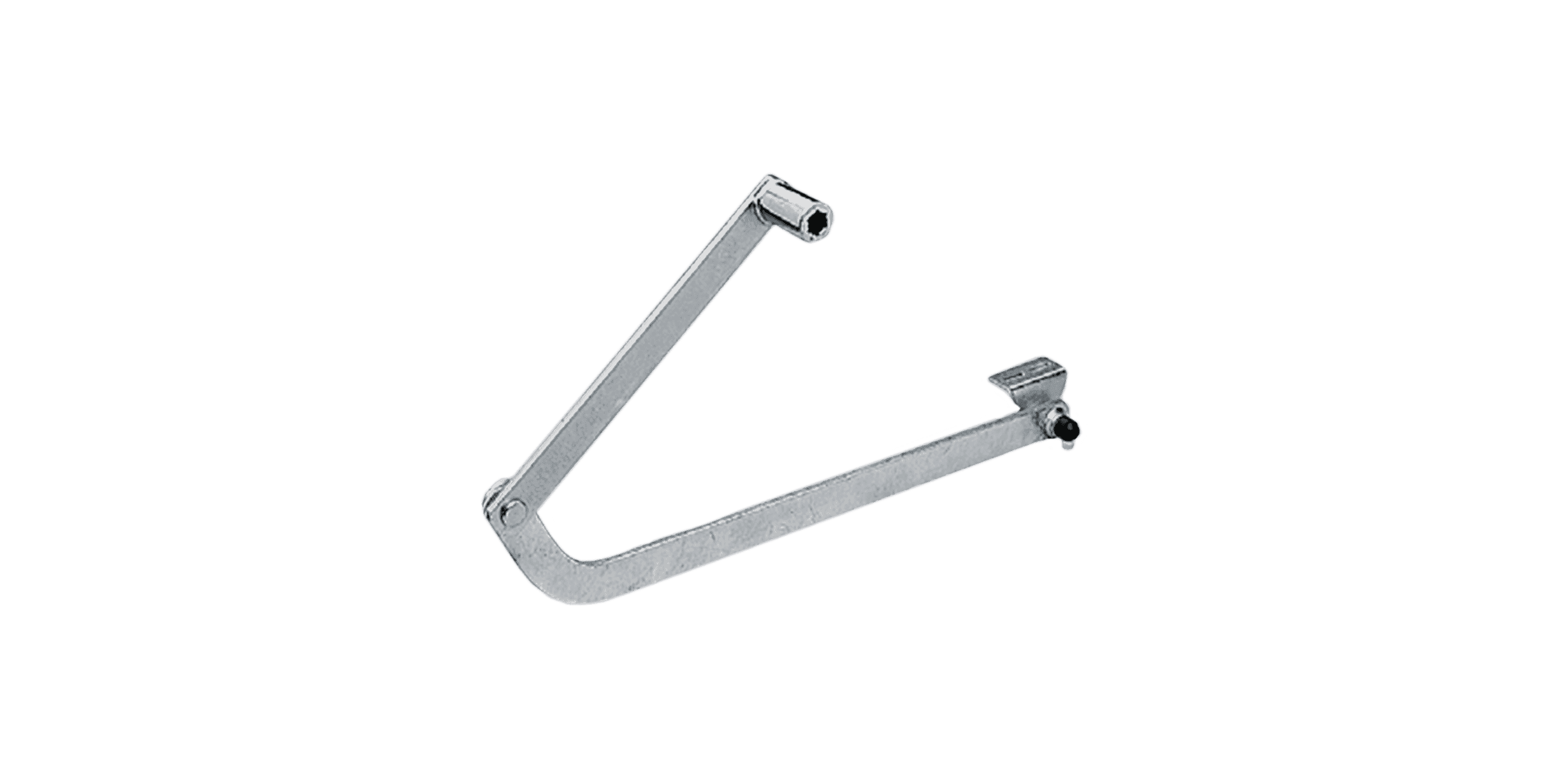

Irreversible 230 Vac electromechanical geared motor | Built-in electromechanical open and close limit switches | Sturdy articulated anti-shearing arm in galvanised steel

Arm not included

| Motor supply | 230 Vac (50-60Hz) |

| Max absorbed current | 1.75 A |

| Torque | 325 Nm |

| Opening time | 13” |

| Duty cycle | 30% |

| Protection level | IP44 |

| Built-in control unit | |

| Encoder | |

| Operating temperature | -20°C /+50°C |

| Lubrication | GREASE |

| Leaf max dimension | 3.0 m |

| Weight | 10.5 kg |

| N. motors per pallet | 42 |

| Kit weight | 34.6 kg |

| N. kits per pallet | 12 |

BRAINY

APPLICATION

1 or 2 actuators for swing gates, opposed sliding gates, hydraulic operators, and industrial folding doors

CONTROL UNIT POWER SUPPLY

230 Vac - 50/60 Hz

MOTORS POWER SUPPLY

230 Vac / 600 W + 600 W

MAIN FUNCTIONS

Integrated LCD display | Integrated 433.92 MHz 64-code radio receiver with 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code) | Removable terminal boards | Automatic, semi-automatic and deadman’s logic | Encoder input to detect obstacles | Separate limit switch inputs for each motor | Open, close, pedestrian, step by step and stop inputs | Separate photocell inputs in opening-closing and in closing phases | Input for N.C or 8K2 sensitive edge | Output for electric lock 230 Vac and 12 Vac/dc | Outputs for configuration as gate open indicator, service light, second radio channel and photocell testing | Output for connecting flashing light | Autosetting of operating parameters (with motors equipped with encoder) | Separate electronic torque adjustment for each motor and operating times | Adjustable slow-downs | Advantouch system to configure parameters and manage radio transmitters| Number of maneuvers | Programming access password | Maintenance warning

HEADY

APPLICATION

1 or 2 actuators for swing gates

CONTROL UNIT POWER SUPPLY

230 Vac - 50/60 Hz

MOTORS POWER SUPPLY

230 Vac / 500 W + 500 W

MAIN FUNCTIONS

Integrated LCD display | Integrated 433.92 MHz 64-code radio receiver with 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code) | Removable terminal boards | Automatic, and semi-automatic logic | Step by step, pedestrian and stop inputs | Separate photocell inputs in opening-closing and in closing phases | Output for electric lock 230 Vac/service light | Output as gate open indicator, second radio channel and photocell testing | Output for connecting flashing light | Separate electronic torque adjustment for each motor and operating times | Fixed slow-downs | Advantouch system to configure parameters and manage radio transmitters | Number of maneuvers | Programming access password | Maintenance warning